Vertical Water Tank Suppliers in Ajman, UAE

Polycom Plastic Industries is a leading Vertical water tank supplier in UAE and it is renowned for its high-quality products.

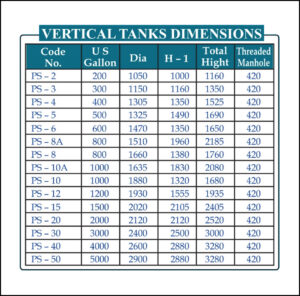

Polycom vertical tanks are engineered to survive temperatures up to 120o F on a sustained basis. Tie-down slots, built-in graduated gallonage indicators, an offset fill-well, and a self-vented, slosh-proof lid feature vertical water tanks and are available in a wide range of sizes and measurements that will accommodate almost any application. Bulk storage tanks, commercial storage tanks, and heavy-duty vertical poly tanks are also referred to as plastic vertical storage tanks. These HDPE tanks receive heavy use for a range of applications in the agricultural, mining, manufacturing, and commercial sectors. The bulk storage of water, pesticides, fertilizer, and diesel exhaust fluid (DEF), acids, and chemicals are common uses.

Features of Vertical Tanks

- A fixed cylindrical roof tank can usually hold up to 20,000 liters of liquid

- To build a tank, the best material is used as liquid materials evaporate or spill out if the tank’s material is of low quality.

- To keep it damage-proof, the storage tank needs careful handling.

- Floating roof tanks have recently been embraced for emissions control by many industries. This kind of tank is special since the roof rises or falls depending on the level of the liquid.

FAQ

GRP water tank (Glass Reinforced Polyester) is composed of panels that have passed through a high-temperature compression molding hydraulic press and have a heat deflection temperature above 200 °C, whereas compressor molding allows both insolubility and infusibility. The water temperature in a GRP water tank does not worsen the material itself at room temperature.

However, there are a few steps you can take to reduce the water temperature in a tank.

Paint It White

This is the simplest method for reducing the water temperature in a tank. It is a well-known fact that light-colored surfaces reflect more light than dark-colored surfaces, which absorb light particles and heat, causing the temperature within the container to rise.

Utilize a Storage Facility under the Ground

Underground storage systems are similar to standard water storage systems, except they are located underground. An underground storage facility has the advantage of not being exposed to summer temperatures. Since the earth is such an excellent insulator, everything under it would be extremely cool.

If you already have an outdoor water storage system, ask your water tank suppliers in Ajman to add it to an underground water storage system to keep it cooler for longer.

Try To Keep In an Enclosed Space

Request your water tank suppliers in Ajman to install the tank either to a closed location or make an enclosed area for your water storage facility. These spaces are especially good, as they provide a great deal of protection against summer heat.

This is especially important when you have a plastic water storage system. Some plastic containers can degrade if you are subject to ultraviolet light so take care of your system of water storage. If this degradation persists, toxic chemical substances can enter the water.

Insulate all Your Water Supply Pipes

In addition, you can also insulate the water pipes to reduce the temperature of the tank. This not only helps you keep the water in summer to a supportable level but also prevents it from freezing in the winter, especially if you live in a region where the weather is cold.

The water pipes can be insulated as follows:

- The use of pipe strips is a traditional way of insulating water pipes.

- Maximize the wall isolation appropriately. It is a technique of insulation that has now become part of common construction strategies to protect the pipes against the harsh outdoor environment.

- If you need to cover long, direct water pipes, you can install foam pipe sleeves. Sleeves can be as long as 6 feet on the market. The sleeves of the pipe are also rubber materials.

- Adding insulation to the areas where pipes enter and exit the walls. Blocking these gaps, in particular around water pipes that reach the outside walls, is essential for weatherproofing and maintains the fluid temperature.

The lifespan of a polyethylene tank cannot be measured well. Numerous variables can impact the tank – which material is stored in the tank? Does the tank work inside or outside? What part of the land are you in if the tank is outside? The outdoor tanks are exposed to more intense sunshine. The outdoor tanks are subjected to intensified sunlight. The lifetime of any vertical tank will be adversely affected by UV rays. Is the tank used for storage or transport exclusively? Each of these elements influences the life span of a vertical tank.

However, according to the vertical water tank supplier UAE, depending on various factors, the average life expectancy of a vertical polyethylene tank is 15 to 20 years or more.

The proper handling and installation of the vertical water tank are very important for long resistance to corrosion and low maintenance over the life of the tank.

Some important instructions are given below to install the vertical tanks:

- The base for flat vertical vessels across all lower sections should be fully and consistently supported. The base should be created to ensure that maximum design loads avoid settling or deflecting.

- The base surface of the supporting base should be nonporous and free of cracks, depressions, and spikes. The support base is often made of reinforced concrete.

- All flat-bottomed equipment should be bolted to the base pad through hold-down lugs. This precaution would reduce the risk of equipment damage caused by the movement of the device at nozzle positions and areas of other attachments.

- Leave enough space between the tank and any nearby structures to allow for expansion after the tank has been filled. A minimum of 150-mm space is required all around. Place the tank in the most convenient location for filling, maintenance, and safety.

- Make certain the tank is shielded from strong winds (especially when empty). Strap it down if necessary.

- After the position has been identified, connect all pipework, fittings, and accessories. To prevent damage to the fittings and tank wall, all pipework and fittings linked to the tank should be supported. To absorb shocks and movement of pipe fittings from the tank, insert a length of flexible pipe. To prevent harm from standing over pipes, place the pipe directly on the ground.

- Water tank stands are appropriate, but they must be installed by a licensed engineer.

- Water storage tanks must be protected by load-bearing walls and a complete underground slab if they are to be installed underground.

- Always move the tank carefully, only when it is entirely empty and away from building material on site.

- Do not stand or climb the tank (especially during filling). The outside of the tank may be slip-threatening.

- If the pipework and fitting are not fully supported, the structure and integrity of the tank seals might be affected.

- Although at Polycom, a leading vertical water tank supplier in UAE, our tanks are extremely long-lasting, inappropriate handling and installation may lead to tank fittings, and supply damage. Failure to comply with the instruction on handling and installation makes all guarantees void.

Polycom, one of the best water tank suppliers in Ajman provides each water storage tank with the longest possible life when properly installed and well maintained.

Water storage tanks are used to conserve clean water generated by filtration systems. Depending on the application's needs, they come in a variety of styles, sizes, and performance capabilities. They play an important role in the industrial, commercial, and municipal sectors. Therefore, it is important to install and maintain these water tanks properly.

The following outlines are provided to show the Maintenance Requirements for Vertical Water Tanks.

- Inspecting the equipment's condition is the first step in any maintenance procedure. Inspections of water storage tanks may be graded as wet or dry.

- Dry inspections, as the name implies, necessitate the removal of all water from the tank until they can be performed by a licensed professional appointed by a vertical water tank supplier UAE.

- Wet checks are carried out without the tank being emptied. A disinfected diver or a remotely operated vehicle (ROV) enters the structure, depending on the tank, to detect potential pitfalls. If severe issues are detected, such as peeling paint or thinning material, the tank will have to be withdrawn from service for repairs.

Regardless of the process, inspections normally begin at the bottom of the tank and work their way up to the legs, rods, struts, and ladder. The thickness of the material, paint, and the adhesion levels of the coating are some of the tank conditions to look for with the help of a professional appointed by a vertical water tank supplier UAE.

- Cleaning your water tank, roof, gutters, and inlet and outlet screenings on a regular basis is essential to ensure consistent and healthy drinking water quality.

- Every six months you have to check the roof, gutters, tank inlets and outlets, and screens.

- Always keep removing leaves, droppings, dead insects, and the like from your roof and gutters.

- Cleaning of the water tank has to be done every couple of years.

Polycom Water Storage Tanks are made from virgin raw materials on cutting-edge machines. Our technology ensures that the tanks are stress-free and have uniform wall thickness for long service life. For water storage, Polycom, a vertical water tank supplier in UAE provides a variety of tanks in a variety of UV-stabilized color choices that are suitable for both domestic and commercial applications. Our research department performs quality checks on a variety of criteria to ensure that the product is of the highest quality. These tanks are commonly used to store various acids, chemicals, and corrosive solutions in various concentrations and temperatures. External layer - UV light protector, Black layer - Sunlight protector, Inside layer - Dirt protector are the insulation layers of the overhead tanks, which minimize water heating and ensure that less energy is used for cooling.

Vertical storage tanks have many benefits, ranging from construction to manufacturing costs and beyond. Horizontal tanks are also useful, but they have different purposes. In contrast to their vertical storage counterparts, horizontal tanks have higher associated costs and components.

Some benefits of storing in vertical storage tanks are mentioned below.

Stability

Vertical chemical storage tanks are more stable. This is because the base's construction allows it to be mounted on a smooth, solid surface.

Pressure Distribution

When it comes to pressure distribution, vertical tanks are a better choice. Vertical storage tanks provided by water tank suppliers in Ajman have a cylindrical shape, which ensures there are fewer stress points and more even pressure distribution. Vertical tanks can store larger quantities of liquid without jeopardizing protection.

Space

Vertical tanks require less space than horizontal tanks, designed especially for smaller spaces.

Cost Savings for Material and Construction

In order to withstand the load, a tank's walls must be thicker as its diameter increases. The fact that vertical storage tanks are typically built to be taller than they wide necessitate thinner tank walls. Since there is less material used in the design and production of the tank, it is inexpensive to make. The bottom plate is the only part that needs to be thicker than the cylindrical walls (this is due to hydrostatic load). A horizontal tank must be the same thickness all the way around as the base plate.

Increased Productivity

Another benefit of a vertical tank's efficient nature is that its height has more available capacity, which helps minimize pumping costs by using gravity. In other terms, compared to a horizontal tank, it produces a more hydrostatic head.